Custom Engineering

LESSONS IN AESTHETICS AND EFFICIENCY

With every new yacht design, Heesen is challenged to find new solutions – advances from which all future Heesen yachts benefit. Currently, the shipyard offers an extensive menu of hull types and innovations to choose from to create the perfect yacht design for each client. Some recent developments include the Fast Displacement Hull Form (FDHF), the Hybrid Solution and Hull Vane technology developed by Van Oossanen.

UNRIVALLED CRUISING COMFORT

For unrivalled comfort when cruising the optimal hull form is matched with a rudder and propeller design that has exceptional hydrodynamic efficiency. For the 80m, nearly 30 knots Project Cosmos, Heesen joined forces with Kongsberg Maritime for the radical new Promas design. This rudder-propeller combination eliminates cavitation, and therefore noise and vibration. A 1:11 scale model was thoroughly tank tested with perfect results.

A POWERFUL PARTNERSHIP

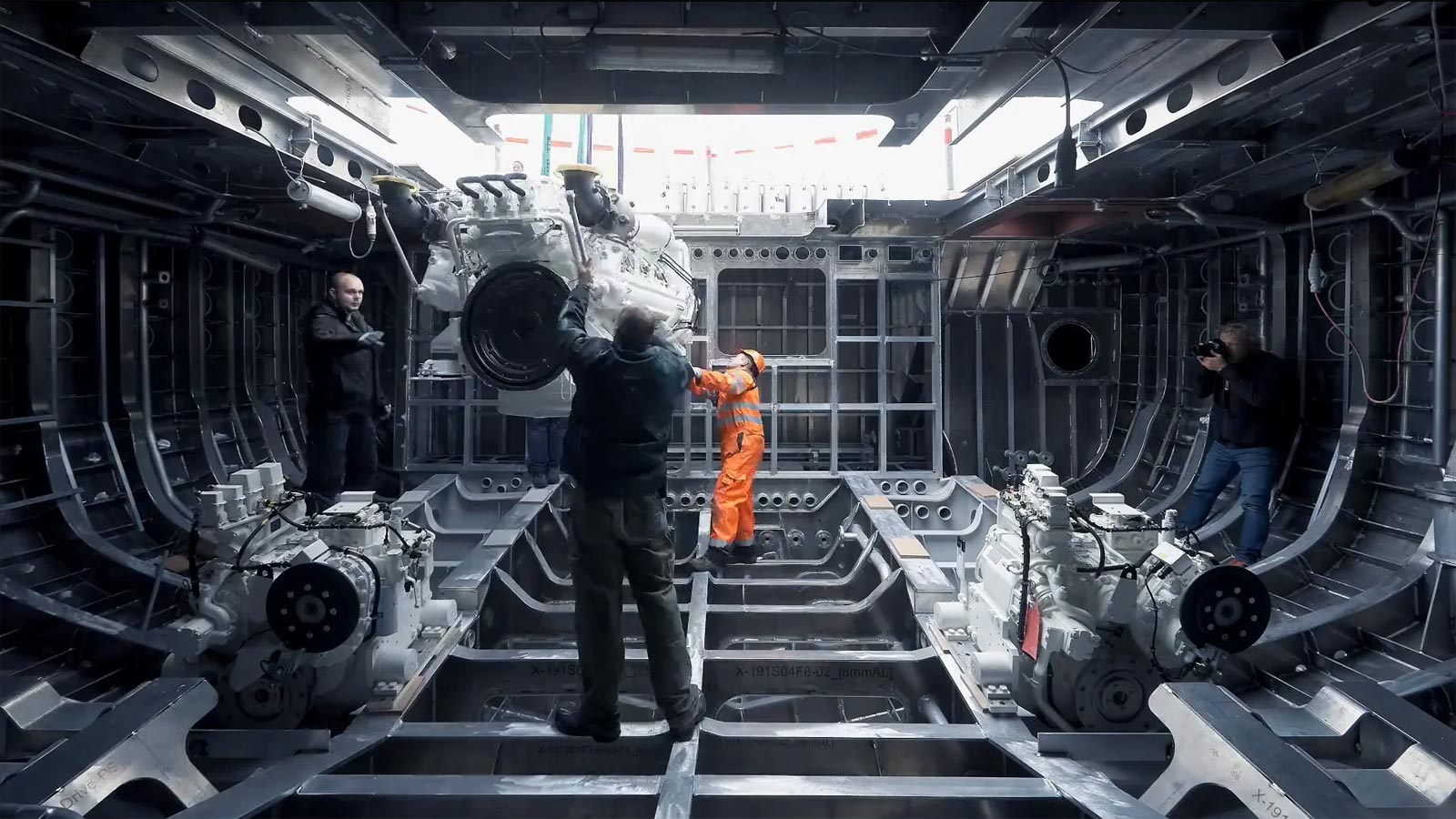

Renowned engine specialist MTU is one of Heesen's most long-term collaborators. Each engine is a work of art, designed to meet the client’s requirements for speed, economy and comfort. In Friederichshafen in the south of Germany, each unit is handcrafted and thoroughly tested, before being transported to Oss. Before the hull and superstructure are joined together, the engines are carefully installed using heavy-duty cranes – it's always an impressive spectacle.

BUILDING A YACHT IS A JOURNEY – WHEN WILL YOURS START?

PLEASE CONTACT US:

Headquarters

Mark Cavendish Chief Commercial Officer

| Robert Drontmann Sales Director

Heesen Yachts North America

Thom Conboy Agent North-America, Mexico, Bahama's & Caribbean