The virtual future of yacht building

Virtual Reality (VR) is poised to have a substantial impact on yacht construction by optimizing both engineering and construction processes. Furthermore, future applications hold promising prospects for the sales and design processes of shipyards and owners, offering a next-level virtual experience that is bound to ignite the imagination.

Our society stands on the brink of a breakthrough in spatial computing. Augmented and virtual reality applications are poised to revolutionize various aspects of our daily lives. Using the new Apple Vision Pro VR headset, watching a movie in a cramped airplane seat can now feel akin to being in your private cinema. AR glasses are anticipated to enhance remote learning for students who lack access to traditional schools. The array of promising applications extends across diverse domains, including yacht building.

Avoiding costly mistakes

At Heesen, the engineering and production departments are harnessing VR technology to further optimize the yacht building process. Ricky Dank, Project Leader of Shipbuilding Engineering, explains, “At the moment we primarily use VR to review and control our work as engineers. VR assists us in identifying and rectifying mistakes, allowing for a closer examination of critical areas at an early stage, leading to significant time and cost savings. This approach provides all parties involved with a clearer understanding of the expected end result, preventing any unpleasant surprises.

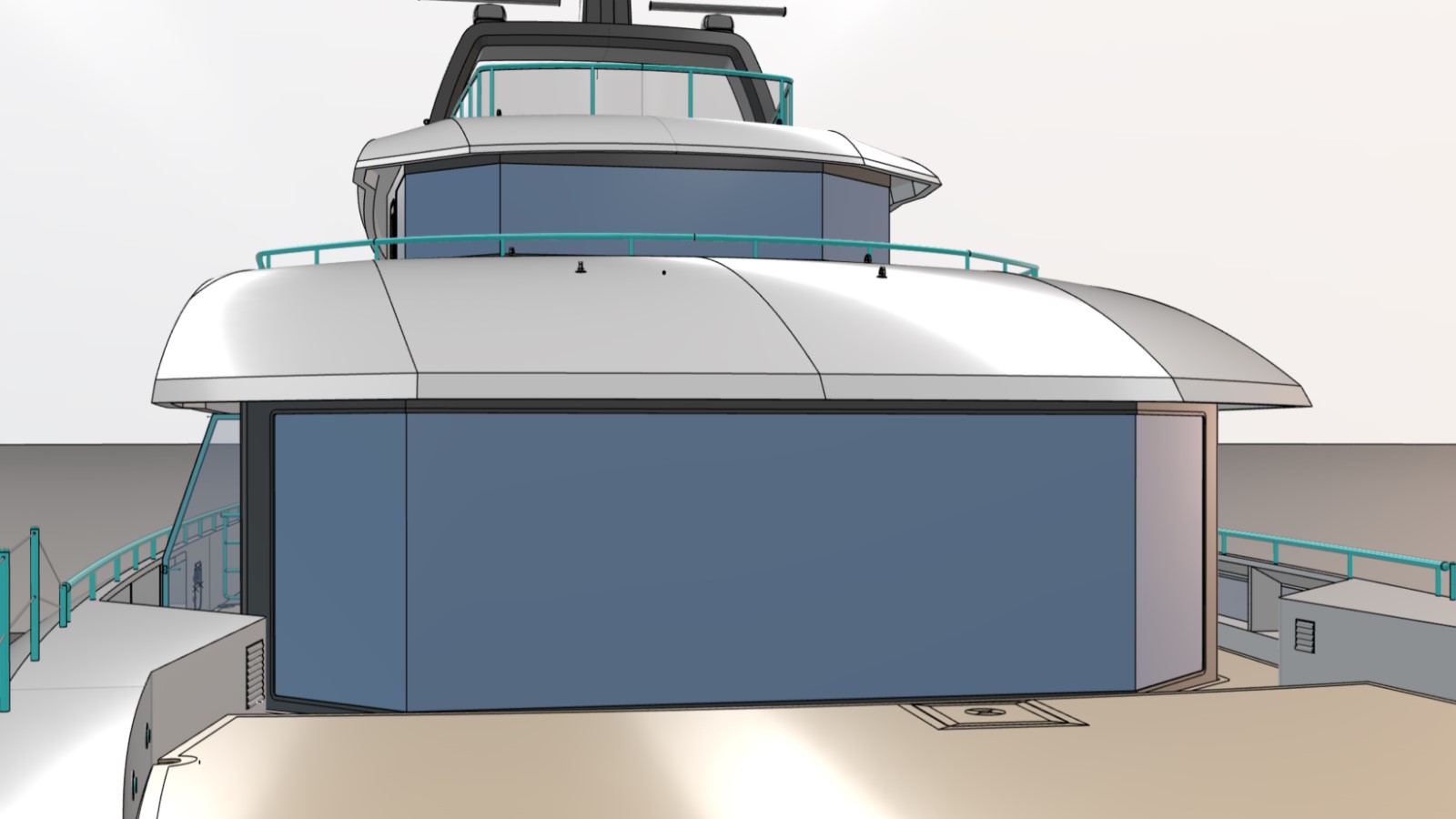

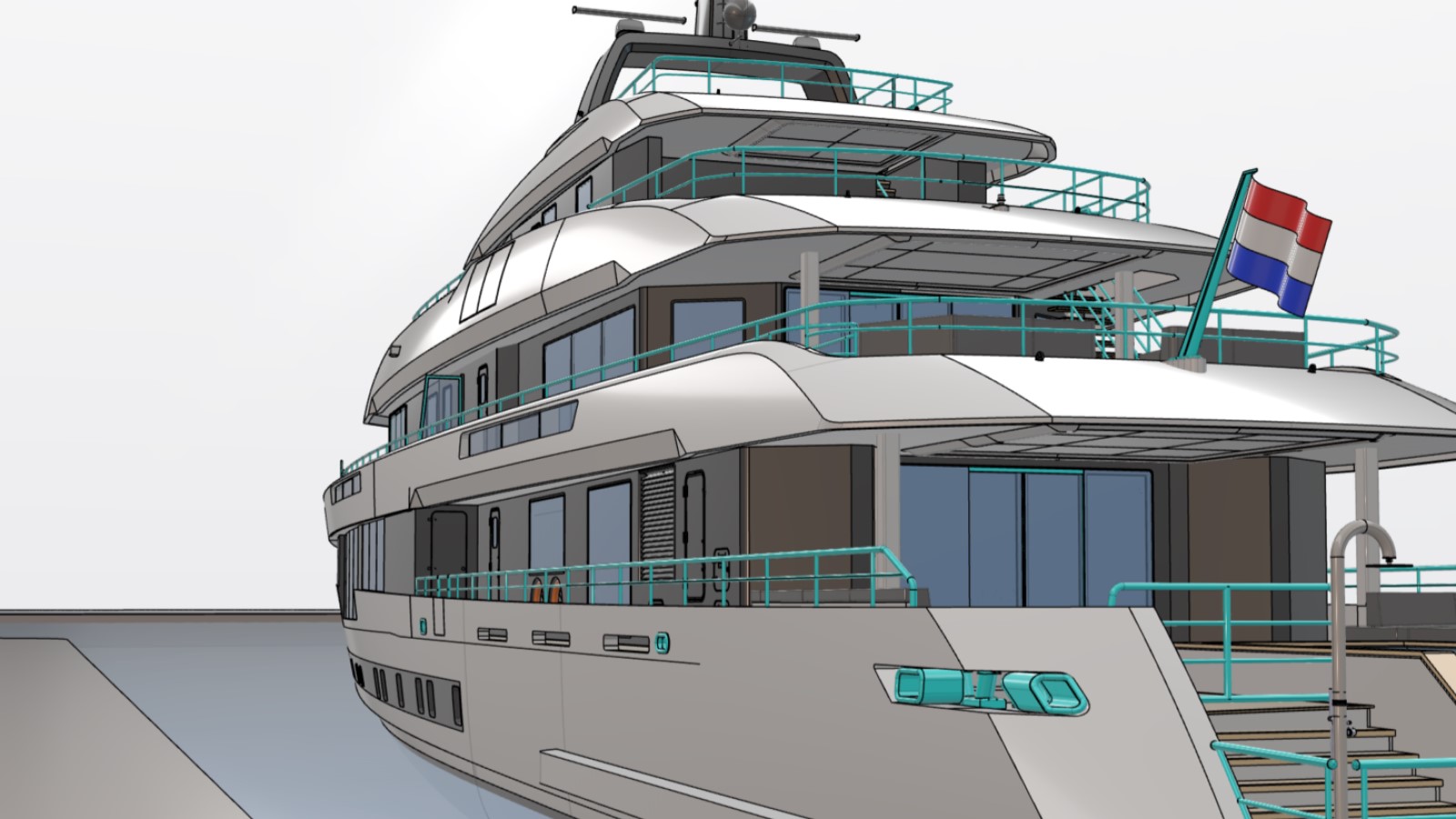

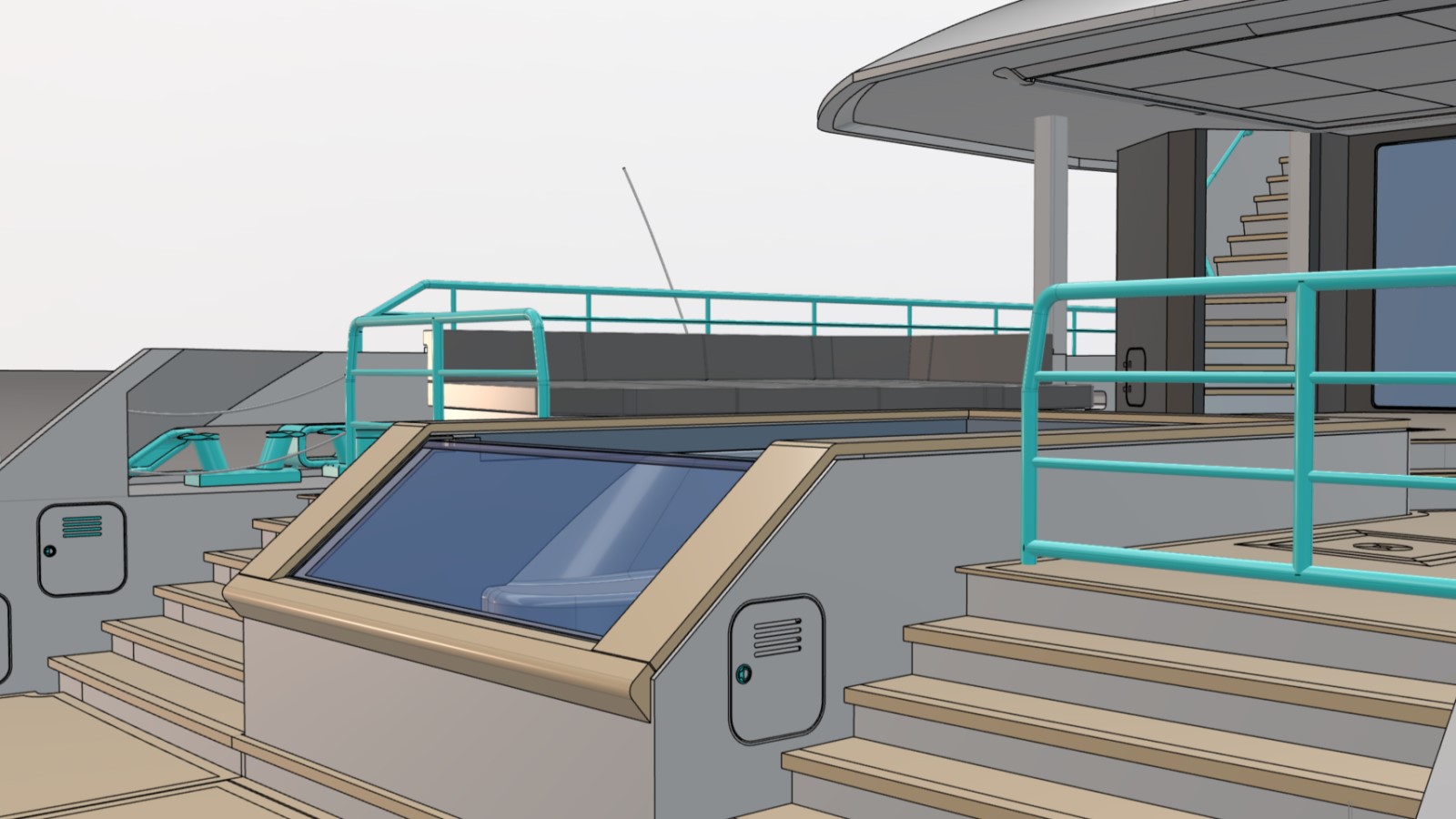

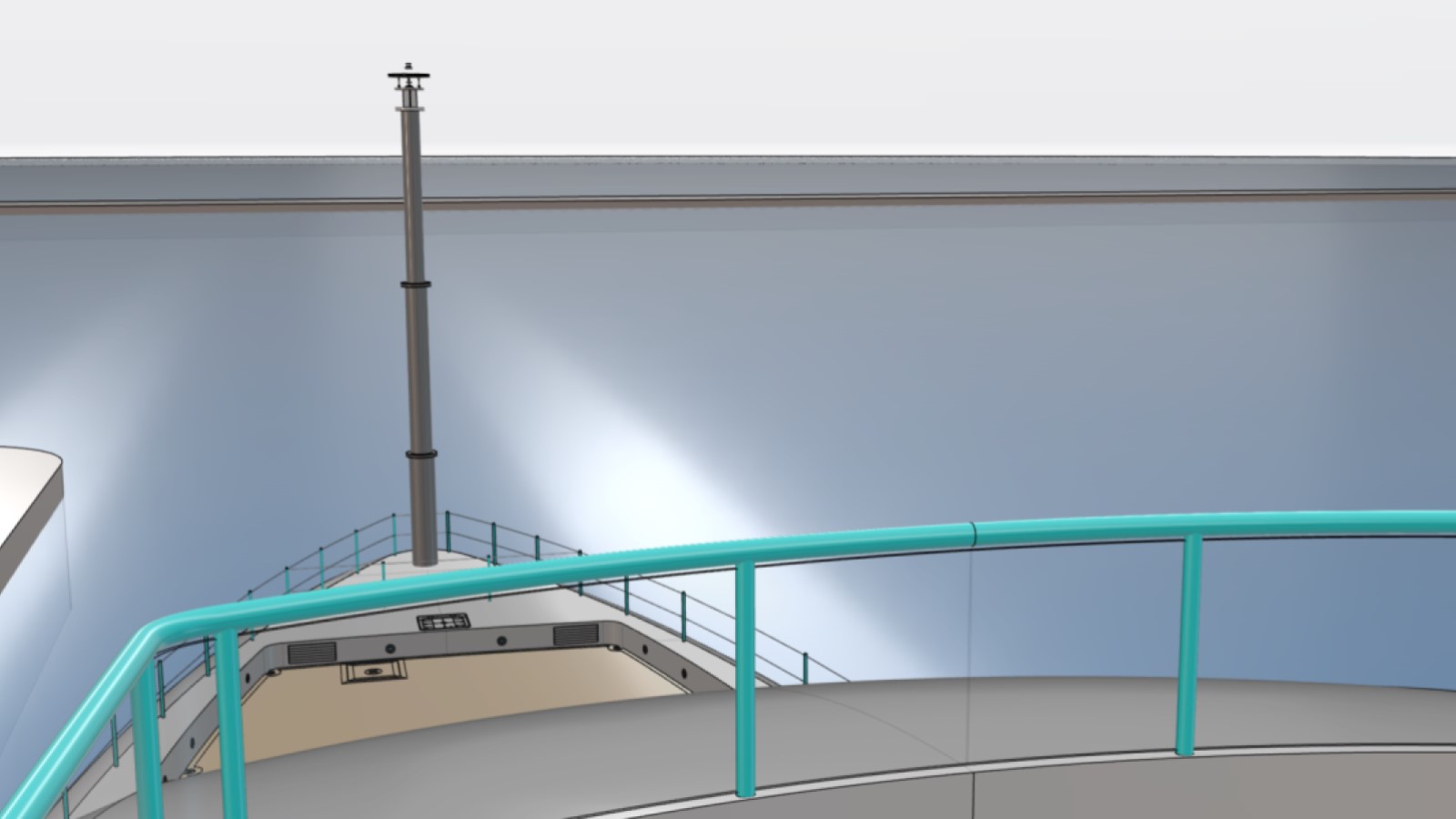

In Shipbuilding Construction, where I work, we implement VR in our outfitting model to delineate all components affixed to the exterior of the yacht, such as doors, hatches, railings, bollards, etc. This proactive measure helps prevent issues like doors colliding with bollards and allows for the optimization of handrail positions. Subsequently, we proceed to work on the 3D models using CATIA.”

Optimising space onboard

Once Ricky and his team complete a segment of the hull, they extend an invitation to their production colleagues for a virtual walkthrough. Ricky elaborates, “We upload all our construction models in a review environment where we can also see the mechanical and interior models. Each model is presented as a layer that can be toggled on or off. If we wish to focus on the piping with our mechanical production colleagues, we activate the mechanical layer. The production departments scrutinize the model from a builder’s perspective—assessing the feasibility of the construction. For example, is there sufficient space inside a fuel tank for welding? Can a wrench be inserted into that hole to tighten a bolt?”

Simultaneously, the 3D models assist in evaluating building logistics. Ricky continues, “We install rails at the ceiling of technical areas, enabling the movement of heavy equipment for onboard installations, such as compressors, pumps, and stabilizers. VR aids us in determining the most efficient installation position and procedure, and an optimal layout that maximizes the limited space onboard.”

Virtual client walkthroughs

Currently, the engineering team still translates 3D models into traditional 2D production drawings, as most production colleagues prefer working with them. Ricky Dank expresses his perspective, stating, “However, I believe it won’t be long before we can eliminate this additional step in the process and build directly from 3D models.”

The design and engineering department already employs the 3D reviews to swiftly obtain feedback and approval from the Owner’s team, managing expectations efficiently. Ricky Dank further explains, “During meetings, we conduct a virtual walkthrough of the vessel, discussing design choices and their implications on layout, construction, and engineering. VR makes it much easier for the engineering team to demonstrate these choices and consequences, streamlining the pre-production and production phases and avoiding costly last-minute design changes.”

Great potential for VR

Heesen has integrated VR into three recent projects: Project Akira, the new 57-metre full aluminium FDHF; the Full Custom 57-metre Project Setteesettanta; and the new 50-metre Steel Series. Ricky Dank emphasizes, “Especially with building Series yachts, our specialty here at Heesen, VR provides us with the opportunity to continually enhance future sister ships. Before commencing the next hull number, together with the Production team, we can virtually walk through the entire model to identify potential improvements in the design and production process.”

Ricky Dank foresees another exciting VR application within Sales, stating, “Experiencing the various spaces on board and having the feeling of standing in a room is very inspiring for future clients. Designers can conduct walkthroughs with clients, showcasing layout options along the way.” He believes that VR is the way forward in yacht building, stating, “We are becoming more accustomed to 3D in our daily lives, and with yachts becoming increasingly complex, I consider VR an essential tool for engineering and building yachts.”

Share

COME AND MEET US: YOU’RE INVITED!

Headquarters

Ruud van der Stroom Chief Commercial Officer

| Robert Drontmann Sales Director

| Eckly Hendriks Sales Manager

Sara Gioanola PR & Press Office Manager

Heesen Yachts Agents

Thom Conboy Agent North-America, Mexico, Bahama's & Caribbean

| Hisham Abushakra Agent for the Middle East region