Optimising propeller and rudder design to improve fuel economy

The route to sustainable yachting is long and challenging. With its BlueNautech initiative, Heesen has committed itself to reducing our industry’s impact on the planet. Discover how innovative propeller and rudder design can improve the propulsion efficiency of yachts.

When looking to lessen a yacht’s environmental impact, propeller and rudder design is easily overlooked. But in its relentless striving for engineering excellence, Heesen has continually pushed naval architects to come up with new and unconventional solutions in all aspects of yacht design. And as Senior Naval Architect Sjoerd van Herk points out, there’s quite a lot at stake in the final stages of a yacht’s propulsion: “Around 40 per cent of the engine’s output is lost at the propeller,” he explains. “So it makes sense to look for improvements in this area.” With sustainability high on the industry’s agenda, shipyards are even more motivated to increase propulsion efficiency. It makes perfect sense: each per cent increase in efficiency means an equal reduction of fuel consumption and CO2 emissions.

Press play if you prefer listening to this content.

The famous Wageningen prop B

Ever since the invention of propeller propulsion back in the 18th century, the problem of propeller efficiency has occupied naval architects. Propeller design has come a long way since then, and continuous evolution has gradually increased efficiency and speed, with innovations in propeller blade design that encompass the shape of the blades, as well as their camber and thickness. One of the biggest breakthroughs came in 1938 with the Wageningen Propeller B-Series, named after the famous Dutch test tank facility where it was created. This type of propeller has been used and improved throughout the 20th century because of its clever design and its efficiency.

Wake-field analysis

More recently the introduction of computational fluid dynamics (CFD) led to another step up in efficiency, because it enabled even more advanced propeller designs, fine-tuned to the specific desired characteristics of the vessel. To optimise propeller design, naval architects carefully analyse the yacht’s wake-field.

“A boat’s wake is caused by the friction of the hull against the water,” van Herk explains. “The displacement of water by the ship causes movement of the water around and behind the hull - a turbulent, non-uniform flow called the wake-field. This is where the propeller operates.” Wake distribution can be simulated using CFD, the resulting data being used to optimise the propeller design to best use the energy of the moving water mass, to propel the yacht as efficiently as possible.

Sjoerd van Herk

Senior naval architect Heesen Yachts

Fine balance

Propeller design is always a balance of various criteria for naval architects to consider. Says van Herk: “Apart from efficiency, comfort is an important factor for superyachts. The propeller causes pressure pulses of water hitting the hull, which cause noise and vibration. In fast, high-powered boats especially, cavitation is another challenge, where low pressure generated by the blades causes the formation and collapse of vapour-filled bubbles, creating a terrible noise on board. So you definitely want to stay within the cavitation limits.”

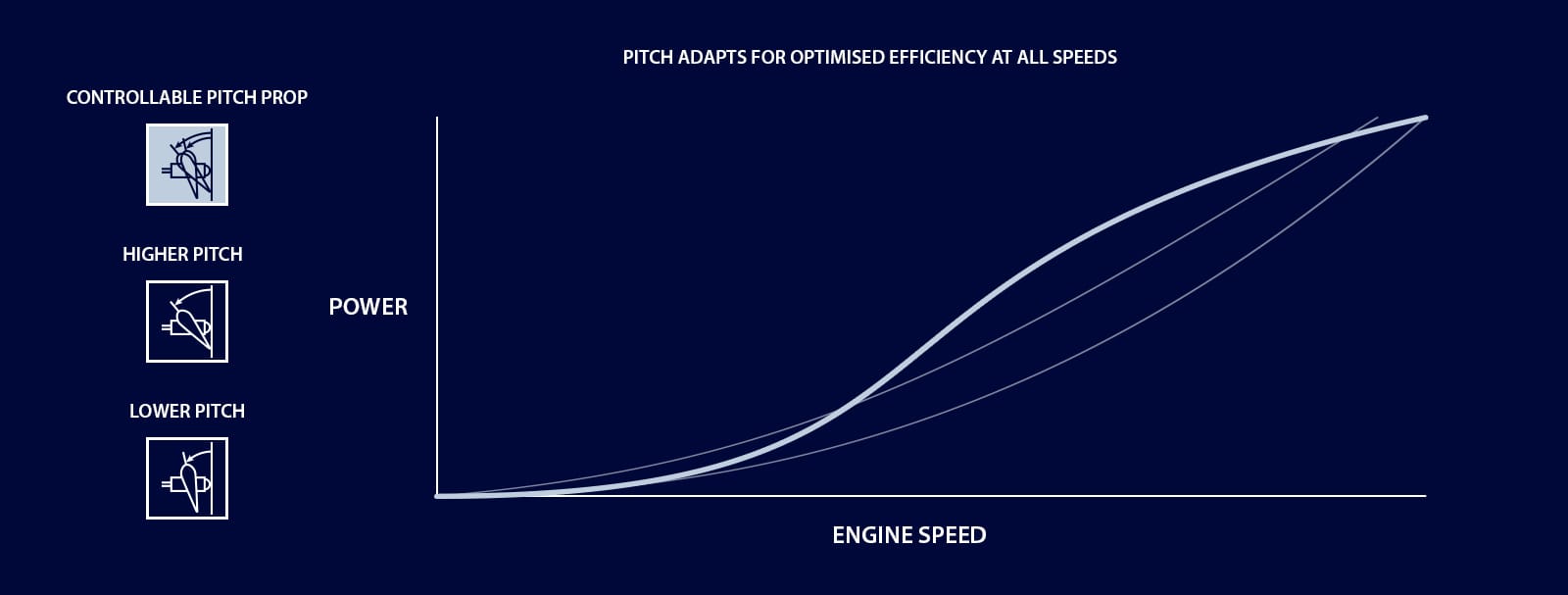

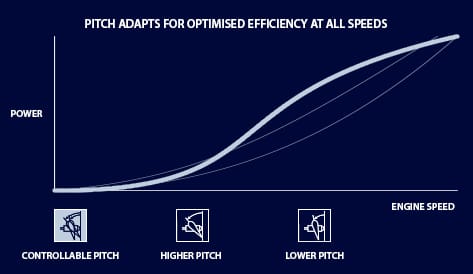

Controllable pitch propellers

Most boats, including the majority of Heesen yachts, are fitted with fixed-pitch propellers, the angle of their blades optimised for a specific cruising speed and load condition. For Project Cosmos, however, Heesen opted for controllable pitch propellers (CPP), which not only enable the yacht to reach an impressive maximum speed close to 30 knots, but also allow it to cruise at speeds below 20 knots without losing efficiency.

“Cosmos is fitted with four engines to enable her to reach her top speed. In this situation the pitch of the propellers is almost fixed to maximize acceleration and performance,” explains van Herk. “However, at cruising speeds the yacht only uses two engines for optimised efficiency. The pitch then continuously adapts to the speed of the engines, increasing whenever possible to reach the engines’ most efficient operating window. This significantly reduces fuel consumption at cruising speeds, which account for around 95 per cent of the yacht’s sailing time.”

Increased pitch reduces fuel consumption

Heesen uses data from the controllable-pitch propellers on Project Cosmos to improve propulsion efficiency on its fixed-propeller yachts. Just like selecting a higher gear in your car, increasing the propeller’s pitch makes the engine run more efficiently, improving fuel economy.

Fuel-saving fixed props

Of course, Project Cosmos is an exceptional full-custom yacht, and the CPP system is a complex and expensive feature with higher maintenance costs. But van Herk and his team of naval architects at Heesen are investigating the possibilities of incorporating the lessons learned into fixed propeller design.

“Based on data collected from our sea trials with Cosmos, we believe we can also direct the pitch of the fixed propeller towards the engine’s most efficient operating window. To further develop this technology it’s a big advantage for Heesen that we also build yachts in Series, so we have real measurements from reference yachts to be able to choose the perfect pitch.”

‘Twisted’ Promas rudders

Another innovative feature that enhances the efficiency of Project Cosmos is her advanced Promas rudder system, developed by propulsion partner Kongsberg. “Ideally, you want the propeller thrust in a straight line, maximizing propulsion,” says van Herk. “But the rotating propeller also creates a swirl in the water, wasting energy. The Promas rudder compensates for this negative effect, and also optimises manoeuvrability by combining rudder and propeller into one hydrodynamic unit.”

This so-called ‘twisted’ rudder is designed with different hydrodynamic characteristics between its upper and its lower part, to counter the swirl and reduce energy loss. The effect is an increase in forward thrust and efficiency gains of between 2 and 6 per cent, demonstrated in extensive tank tests at the Kongsberg Hydrodynamic Research Centre (HRC) in Sweden.

Crystal ball

Of course we want to take a peek into van Herk’s crystal ball to see what the future holds for propulsion efficiency. “CFD and tank tests will help us find new ways to further reduce energy losses from props and rudders, but these will be evolutionary,” he says. “However, as part of our comprehensive, long-term BlueNautech strategy to make all aspects of yachting more sustainable, these will be cost-effective innovations and relatively easy to adopt, so it’s really a no-brainer to keep working towards that goal. Furthermore, improvements in hull design, propeller efficiency and weight reduction, together with other BlueNautech innovations, will bring zero-emission propulsion a step closer. With all these improvements, we can use less powerful and more fuel-efficient propulsion systems on yachts; now and in the future, with sustainable energy sources, like hydrogen.”

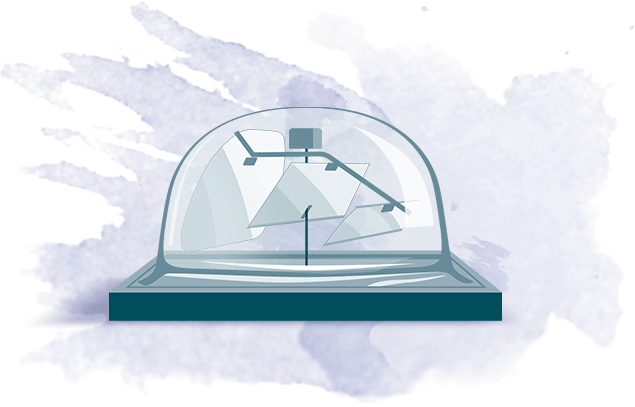

SMART LIGHTING

Instead of conventional lighting, the Heesen offices are illuminated by smart skylights, which use solar-powered GPS sun-tracking technology with mirrors to make intelligent use of sunlight throughout the day, representing an electricity saving of as much as 80 per cent.

SOLAR POWERED SHIPBUILDING

By installing solar panels on most of the shipyard’s building sheds, Heesen makes optimal use of renewable resources and improves its operational footprint.